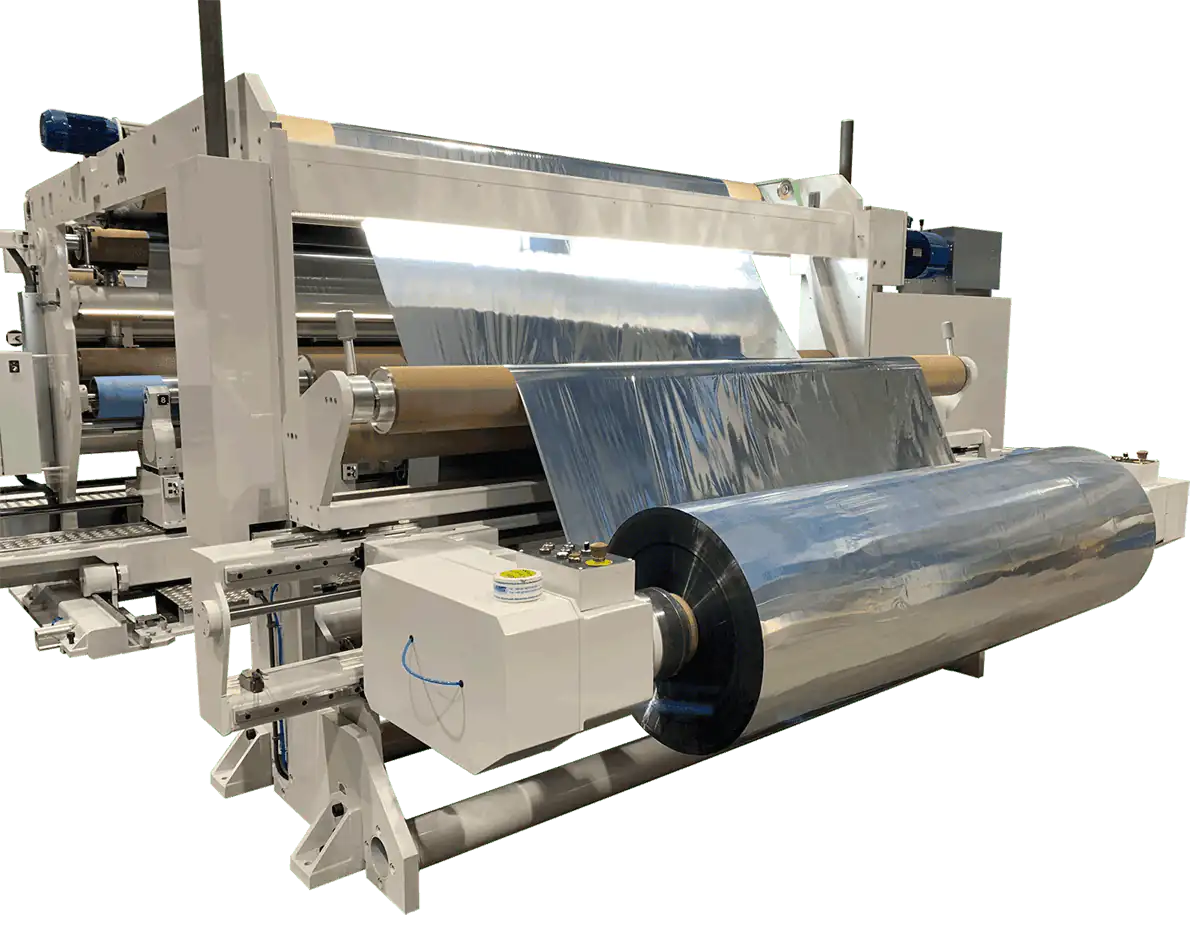

Jade Folienschneider-Aufwickler

Die Jade series is designed to improve the winding quality of all films at high speeds, adding höhere Flexibilität on machine setup, making it one of the best secondary slitter rewinders on the market in the UK.

Anfrage

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.

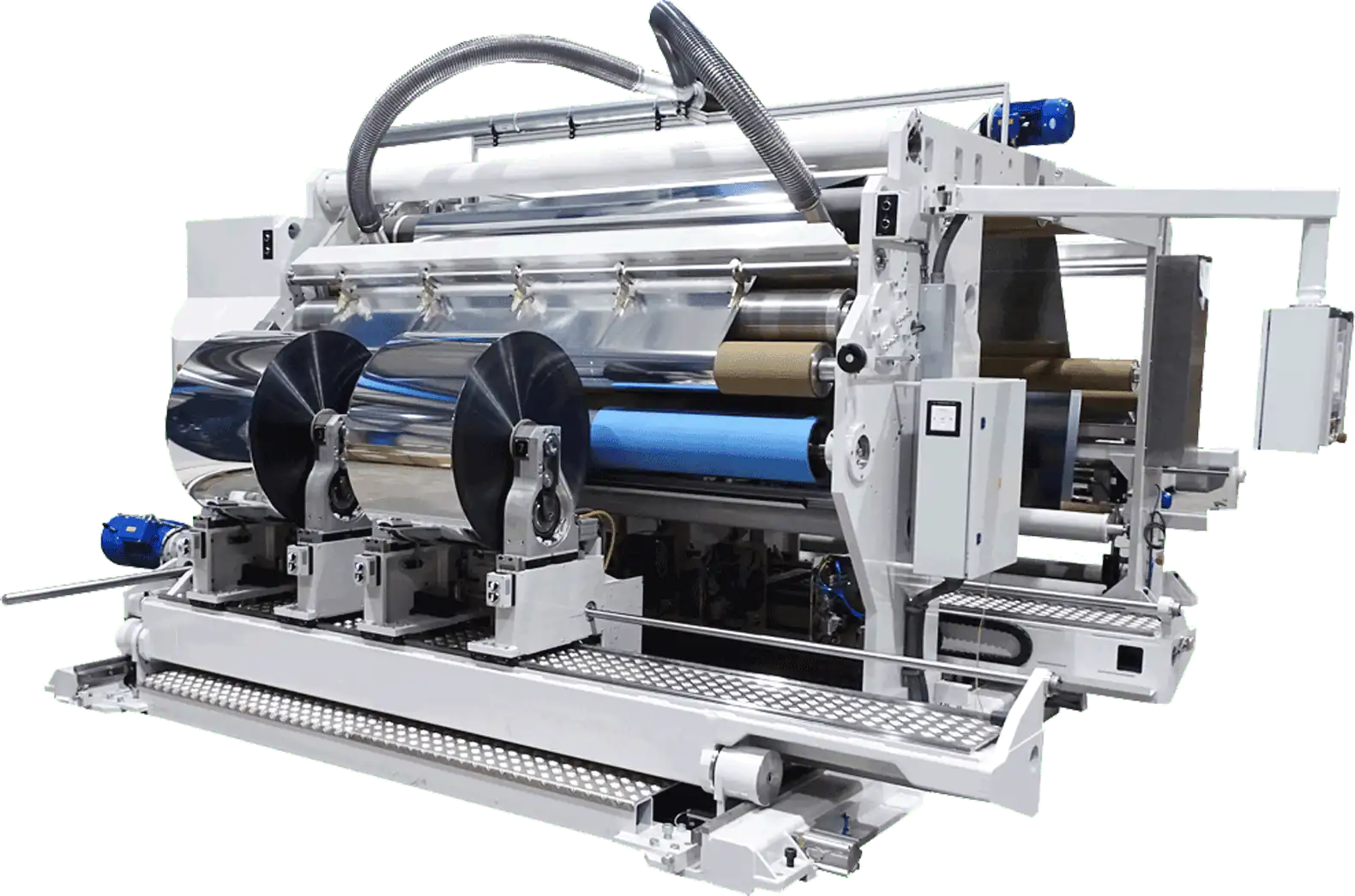

JadeSekundärfolienschneider Aufwickler

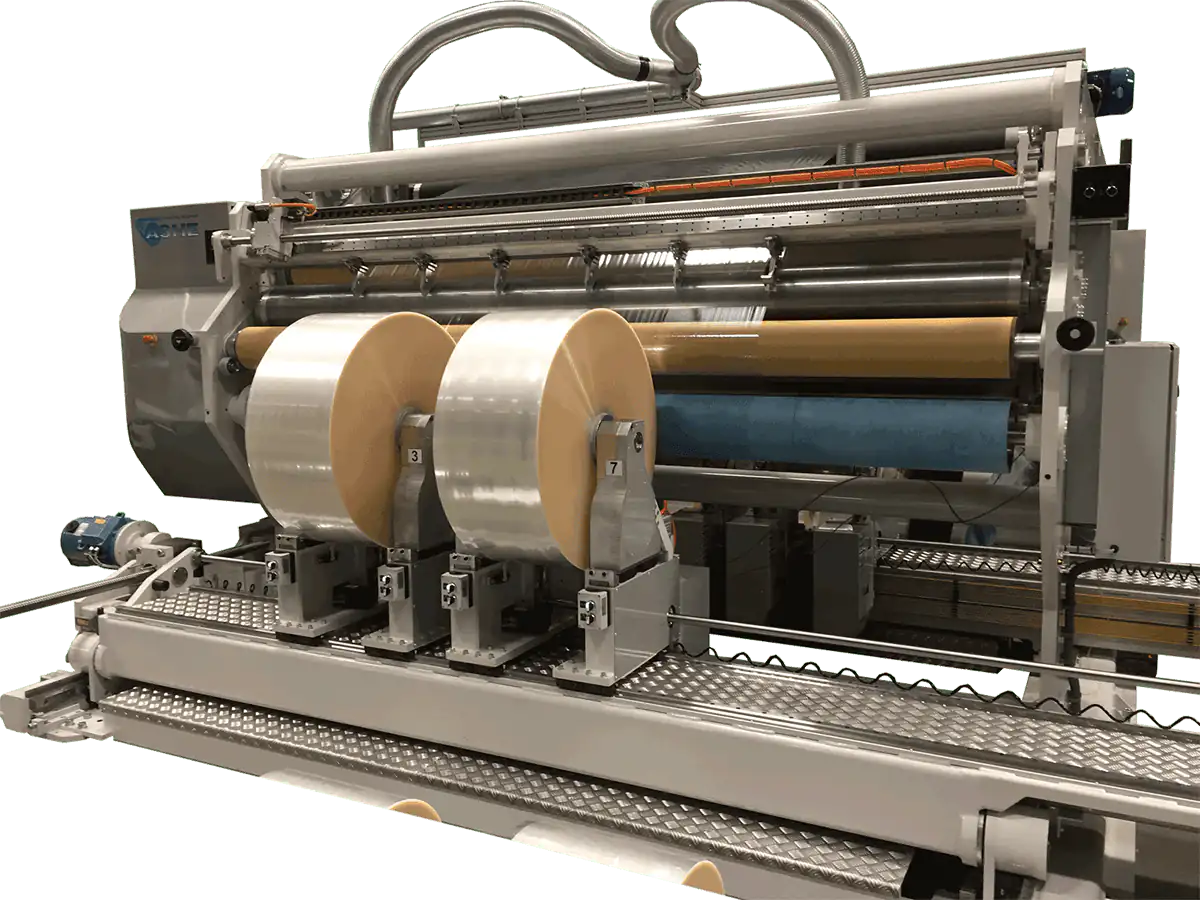

The updated concept of our Jade secondary model slitter rewinder with individual rewinding stations has been developed for film manufacturers and converters who are looking for perfect finished roll quality in minimal time.

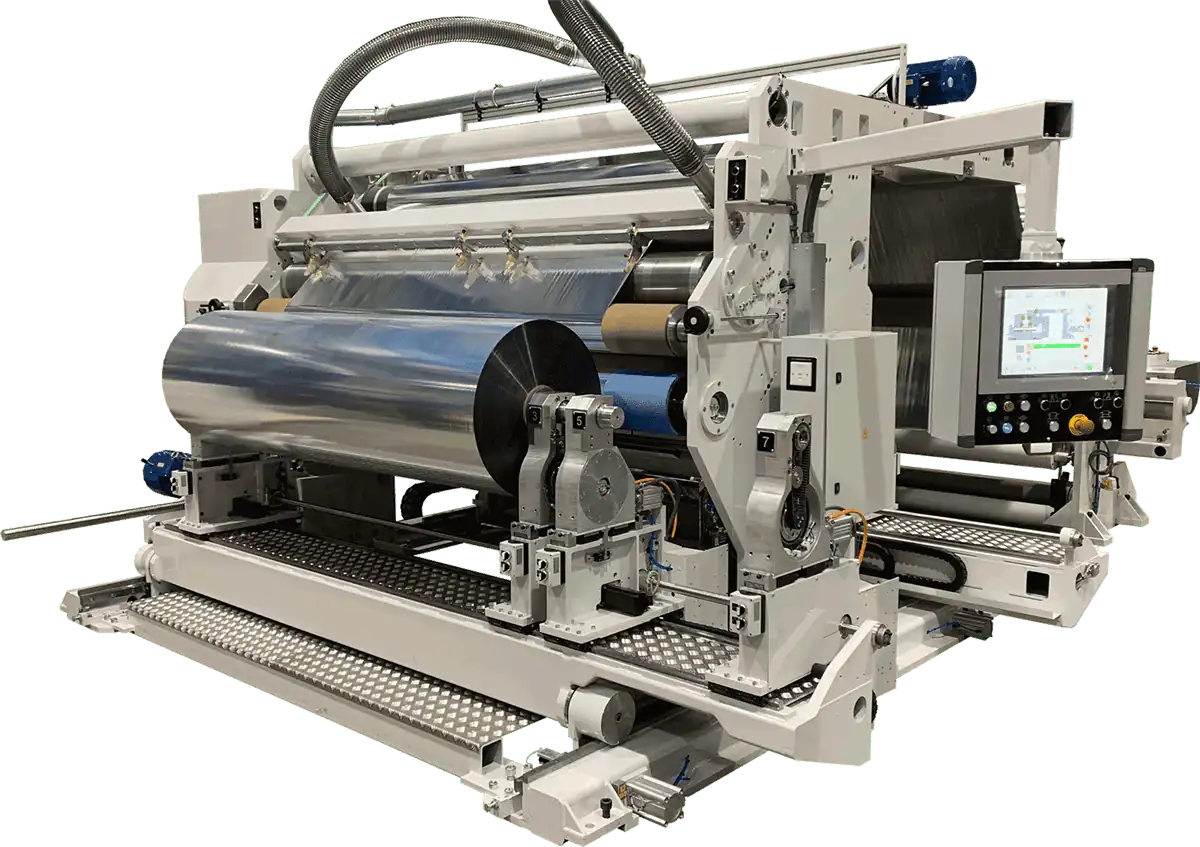

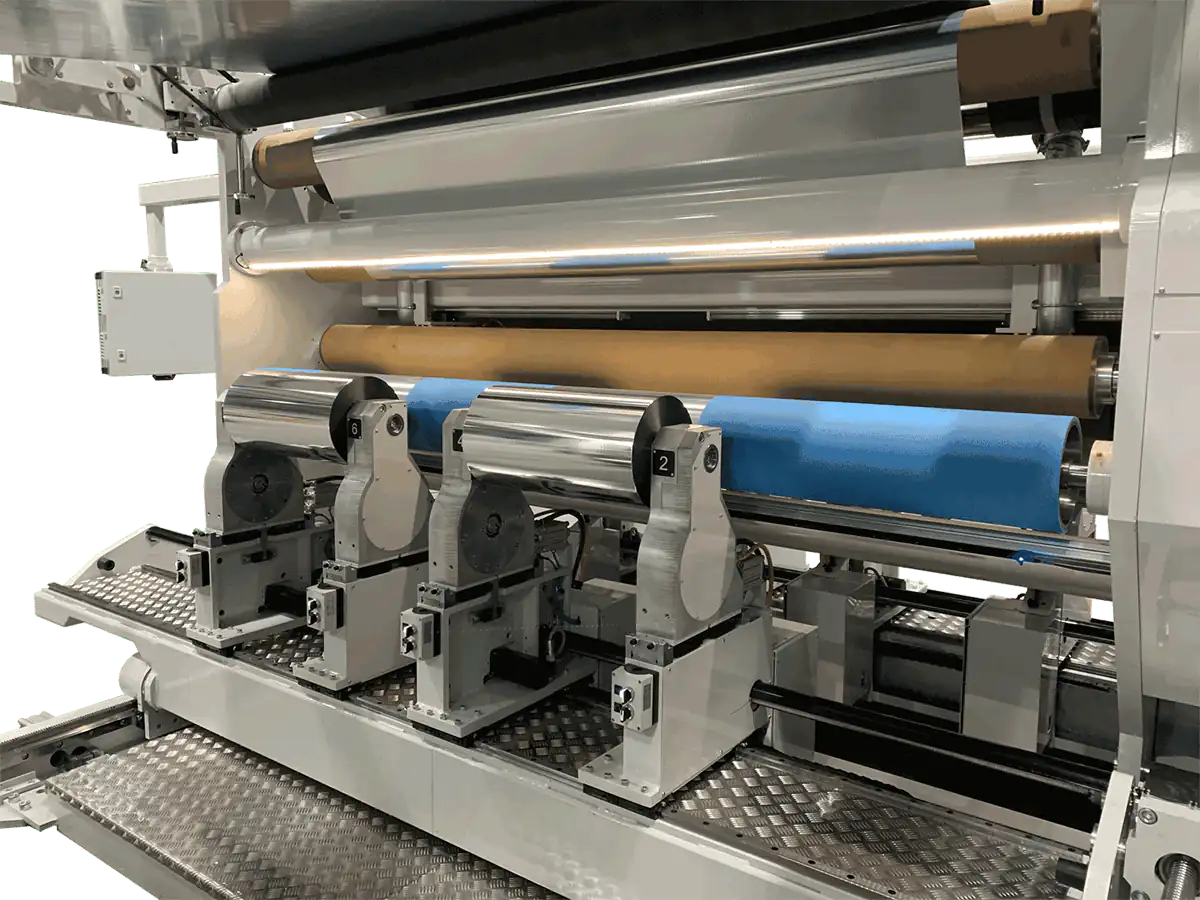

The machine’s design is based on our proven technology of a linear winding system and single contact (lay-on) roller per rewind beam. This eliminates the need to change lay-on roller positions when changing slit patterns. As the contact roller is also driven, the machine is able to offer different winding configurations to give any product perfectly finished roll profiles, making it the ideal secondary slitter rewinder for a range of uses.

The machine has been designed with flexibility in mind; therefore, the design can be suited for all film manufacturers, whether BOPP, CPP, BOPET, PA, metallised or coated films. The machine can also easily be configured for converters of papers and films, laminates or any other speciality product that needs converting.

Different unwinding systems are available on the machine, along with all the different slitting configurations to slit and rewind most substrates. Automation is available with simplified automatic knife and rewind arm positioning systems, which require minimal maintenance.

- Merkmale

- Spezifikationen

- Galerie

- Video

- Broschüre

- All electric operation, meaning no hydraulics are used at all on the machine

- Einfach zu installieren und zu warten

- Verschiedene Schlitzsysteme für die meisten Anwendungen verfügbar

- Vakuumrolle für perfekte Spannungsisolierung verfügbar

- Semi-automatic knife or rewind arm positioning available

- Vollständige Automatisierung der Messer- und Aufwickelarmeinrichtung ist ebenfalls verfügbar

- Linear winding system away from contact (lay-on) roller

- Unloading of the rolls onto a simple trolley to full conveying systems available

- Vollständige Ferndiagnose

- Servo-driven rewind motors

- Centre and centre surface winding possibilities

| Materialbreite | Maximum 4000mm (158″) |

| Durchmesser der Mutterrolle (Abwickeln) | Maximum 2500mm (98″) |

| Fertiger Rollendurchmesser (Aufwicklung) | Maximum 1200mm (48″) |

| Schlitzmethoden | Rasiermesser Rotierende Schere Bersten |

| Minimale Schnittbreiten | 250mm (10″) |

| Maximales Gewicht der fertigen Rolle | 3000kgs (1363lbs) |

| Geschwindigkeit der Maschine | Bis zu 1200m/min (3940ft/min) |

Laden Sie diese Broschüre als PDF herunter:

ASHE ProduktpaletteSekundär-Rollenschneider AufwicklerHauptmerkmale

Sind Sie bereit?

Discover why our clients choose us for their slitter rewinders and converting machinery.

Anfrage

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.