Sapphire S2T

This is the right choice of slitter rewinder for the converter looking for máxima productividad y mínimo tiempo de inactividad. Esto se consigue con la máquina seguir corriendo whilst the operator (or machine) takes off the finished rolls and puts new cores onto the rewind shaft.

Consulta

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.

Sapphire S2TCortadora rebobinadora de torreta dúplex de banda ancha

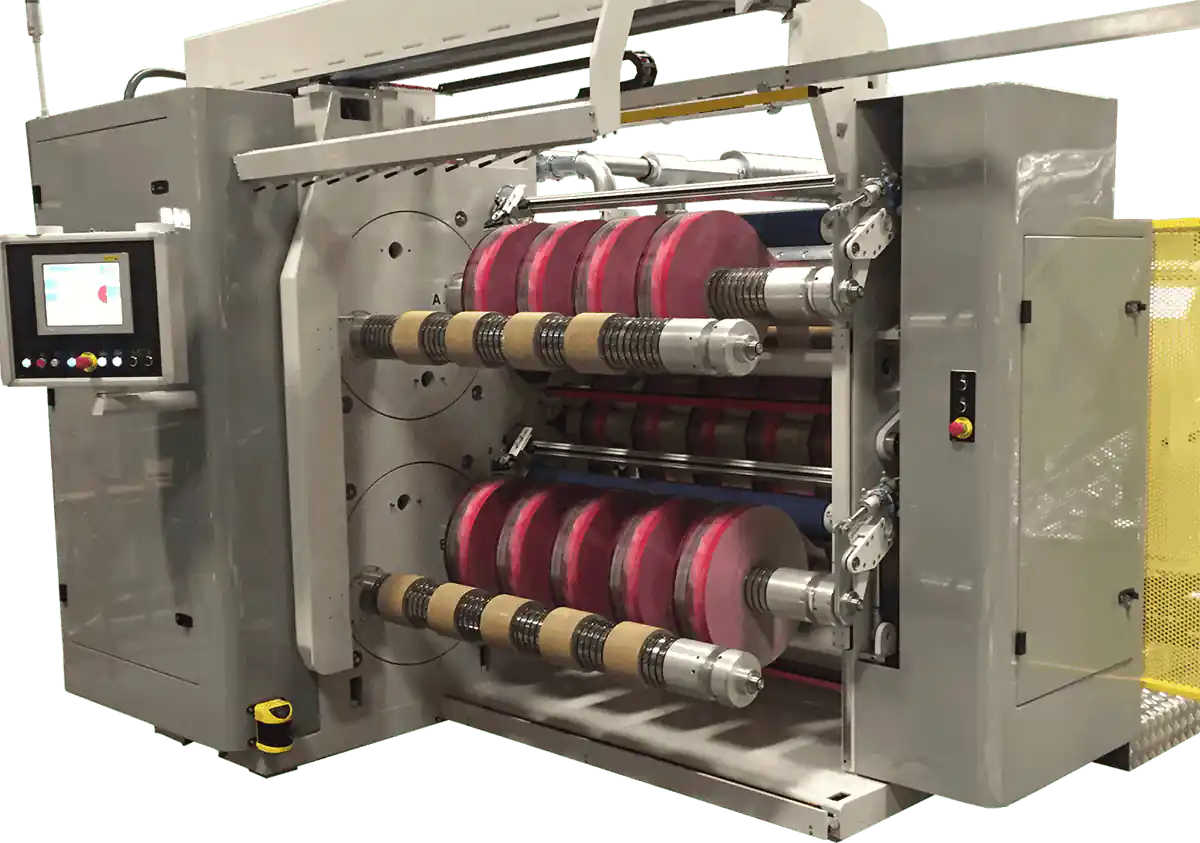

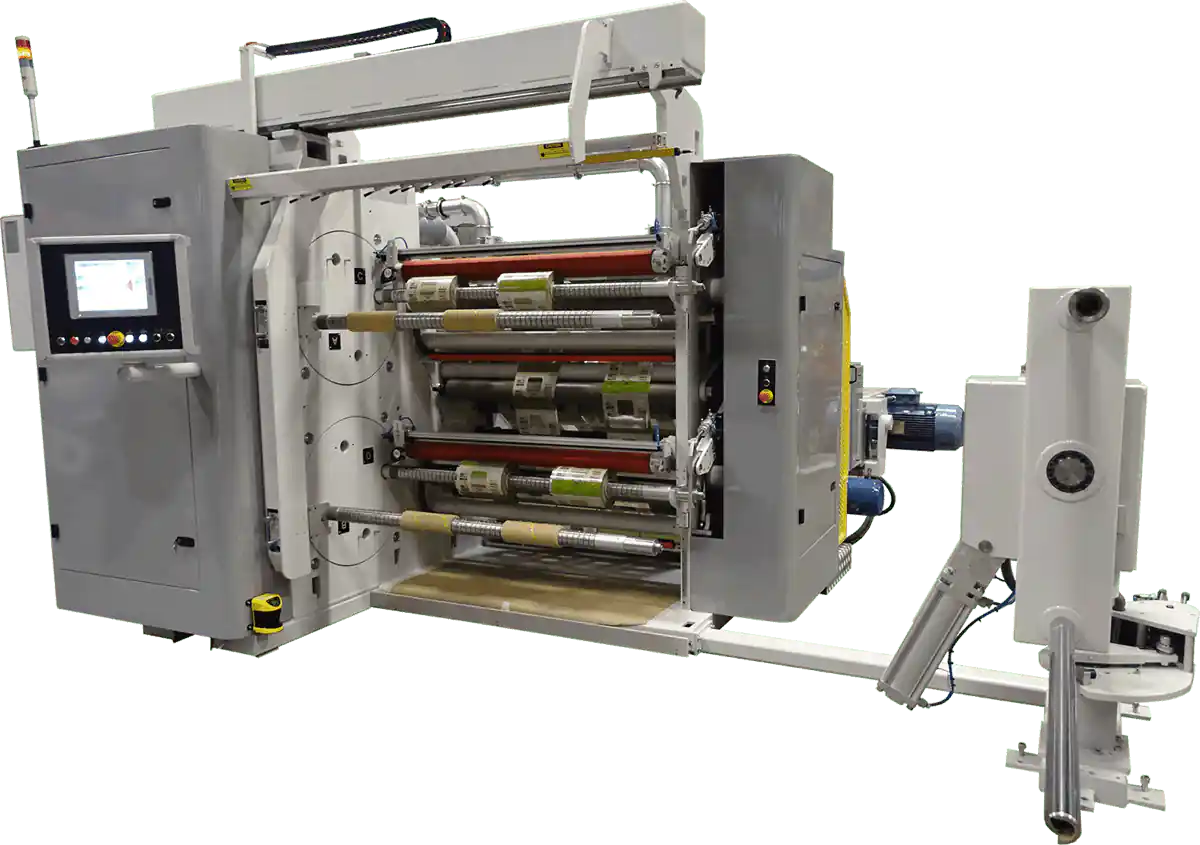

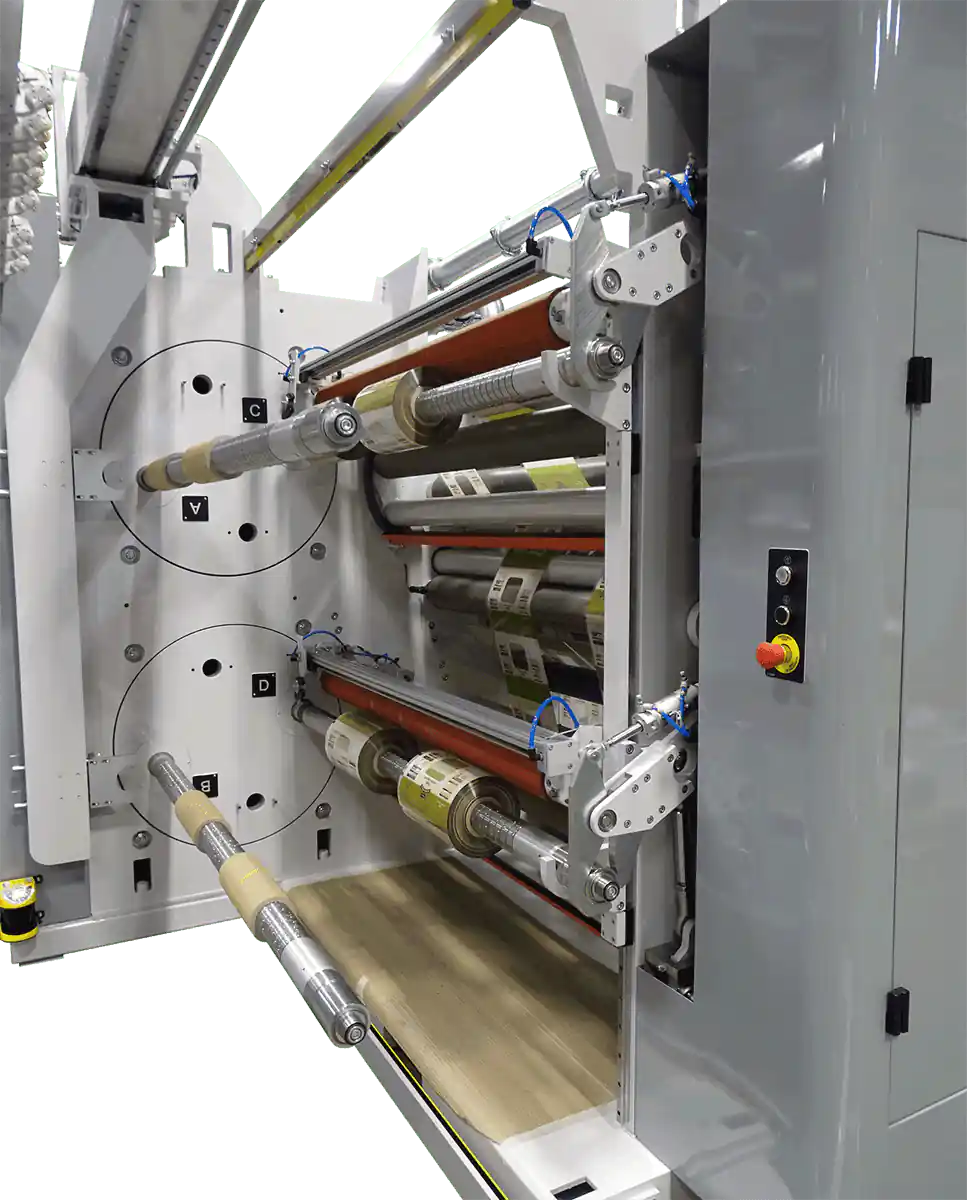

The key benefit of duplex turret slitter rewinders for users is productivity. This is achieved by the machine continuing to run whilst the machine, or operator, is offloading finished slit rolls and re-coring the rewind shafts. On duplex machines, the machine is not running; however, this loss of productivity can be reduced on a duplex turret slitter rewinder type of machine as the four rewinding shafts (two on each turret ring) ensure that the machine continues to run whilst these procedures are taking place.

The design of the Sapphire S2T is based on our Sapphire S2 duplex machine. No hydraulics on the machine makes it a clean operation for flexible packaging and medical applications, and the latest control technology makes the machine easy to use, with a minimal web path length. Easier and quicker setup times can also be implemented on the machine with further automation options, such as automatic knife and rewind core positioning systems.

The machine incorporates our unique ‘turret shaft support’, which ensures that the rewind shafts remain fully supported through the turret cycle. Due to this support, the machine is able to offer very fast cycle times, from the time the machine stops when the set length has been reached to the time it starts the next run.

The versatility of being able to run different substrates with no operator intervention or maintenance is achieved through our vacuum roller along with our driven lay-on roller system.

A range of roll-handling solutions on the rewind side of the machine can also be implemented on the machine, from simply fixed pedestals though to full robotics.

- Características

- Especificaciones

- Galería

- Vídeo

- Folleto

- Desenrollado separado sin eje con movimiento independiente de cada brazo

- Electric roll lifting system, which uses no hydraulics

- Desenrollado con freno o accionado con rodillo bailarín

- Mesa de empalme en el desenrollado para la unión de rollos

- Full web guiding with ASHE’s own edge/line guide for all materials

- Rodillo de vacío para aislar la tensión

- Todas las formas de corte longitudinal se pueden acomodar en la máquina

- Full automation can be offered with automatic knife/blade positioning available for all forms of slitting

- Laser-aided positioning or digital readout systems available for slitting

- ASHE differential (friction) winding shafts, which require NO LUBRICATION

- Sistemas de bucle abierto o cerrado para el control de la tensión de rebobinado

- Motor y accionamiento en cada eje de rebobinado de serie

- Driven lay-on (contact) roller system with different widths available

- HMI intuitiva con almacenamiento en memoria

- Diagnóstico remoto completo con posibilidades de transferencia de datos

- Motores y accionamientos independientes para cada eje de rebobinado

- Sistema completo de soporte del eje de la torreta

- Automatic cross-cut system

- Tiempos de ciclo de la torreta extremadamente cortos

| Ancho del material | 1000mm (40″) to 2000mm (80″) |

| Diámetro del rollo madre | 1800mm (71″) |

| Diámetro máximo de rebobinado | 450mm (18″) & 600mm (24″) |

| Métodos de corte | Todos los métodos de corte disponibles |

| Anchos de corte | Minimum 25mm (1″) |

| Velocidad de la máquina | 800m/min (2620ft/min) |

Descargue este folleto en formato PDF:

Gama de productos ASHESapphire S2T Cortadora rebobinadoraCaracterísticas principales

¿Estás preparado?

Descubra por qué nuestros clientes nos eligen para sus cortadoras rebobinadoras y maquinaria de conversión.

Consulta

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.