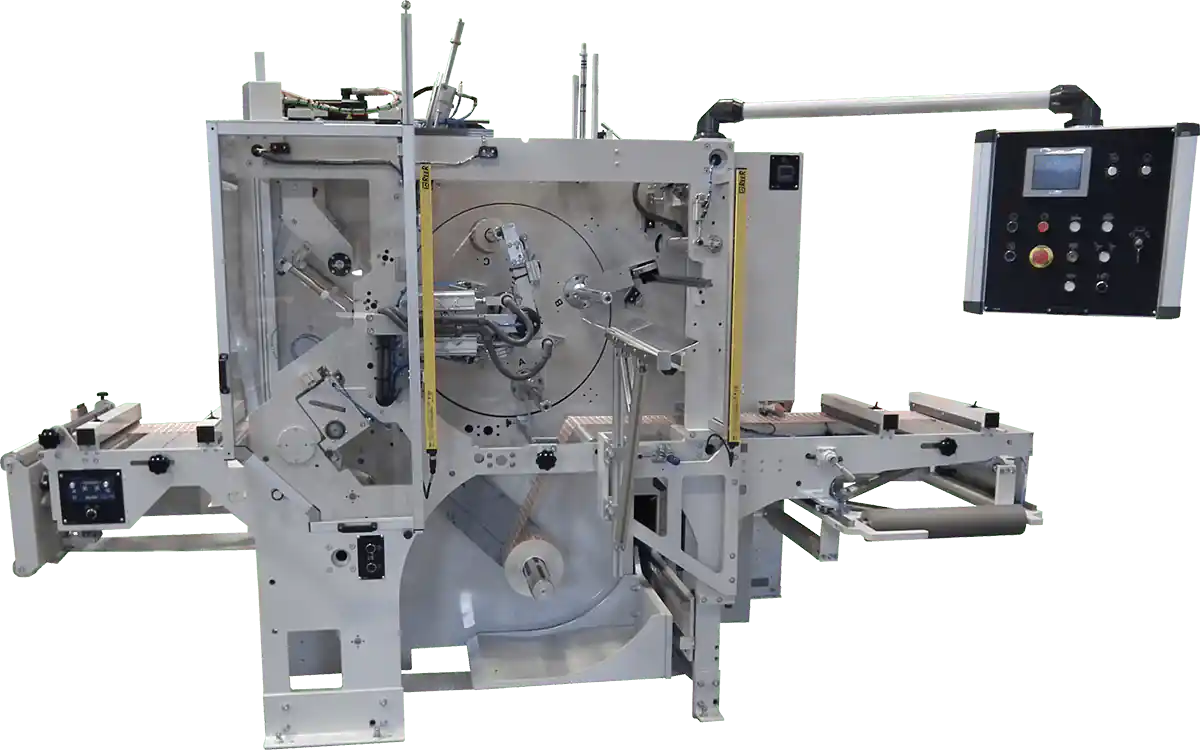

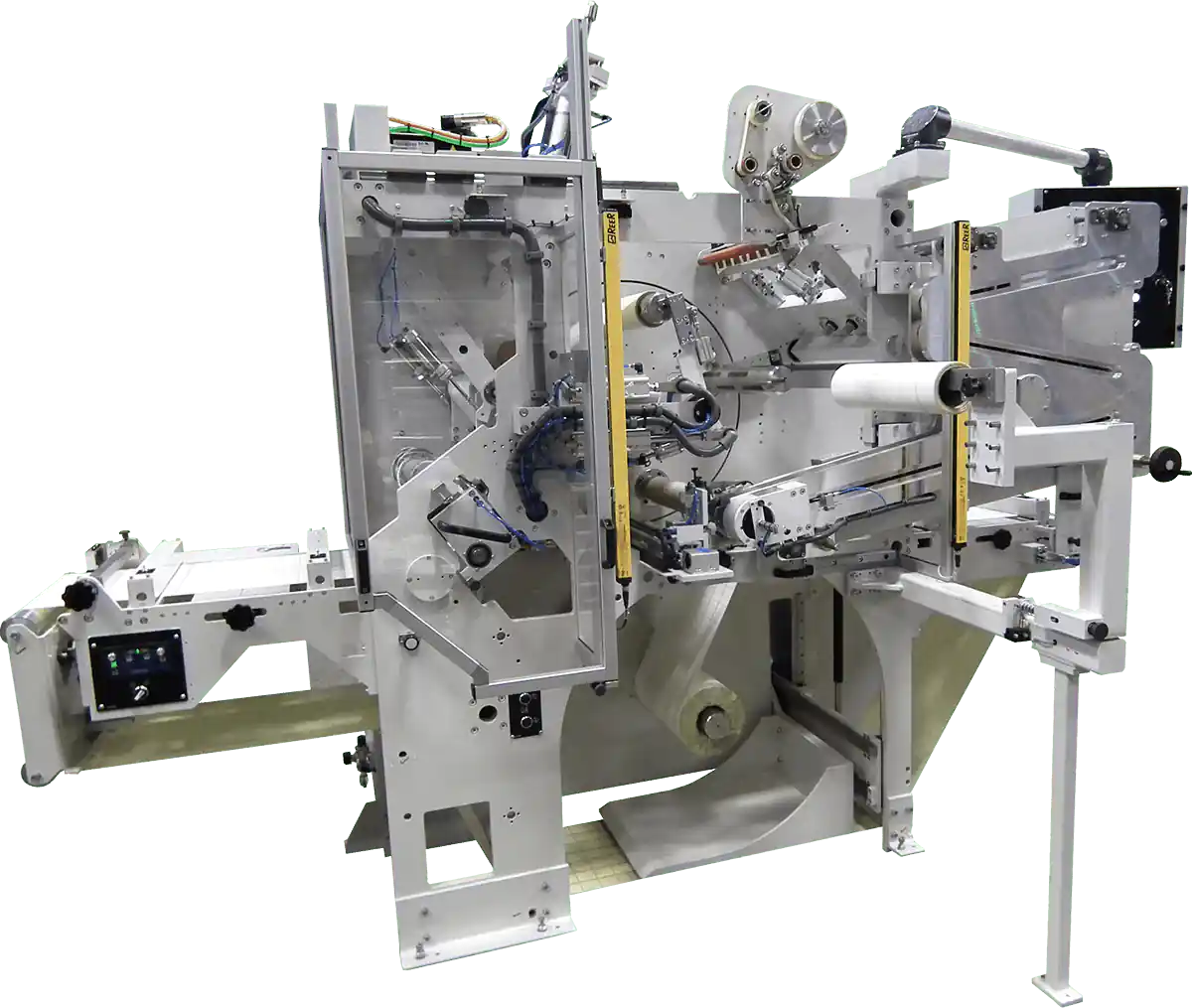

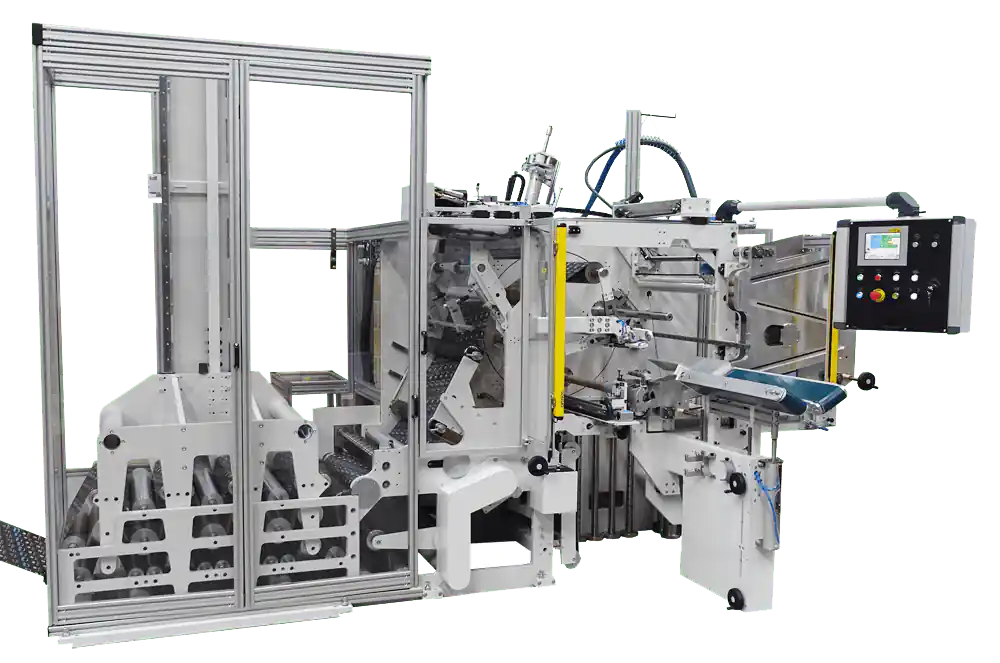

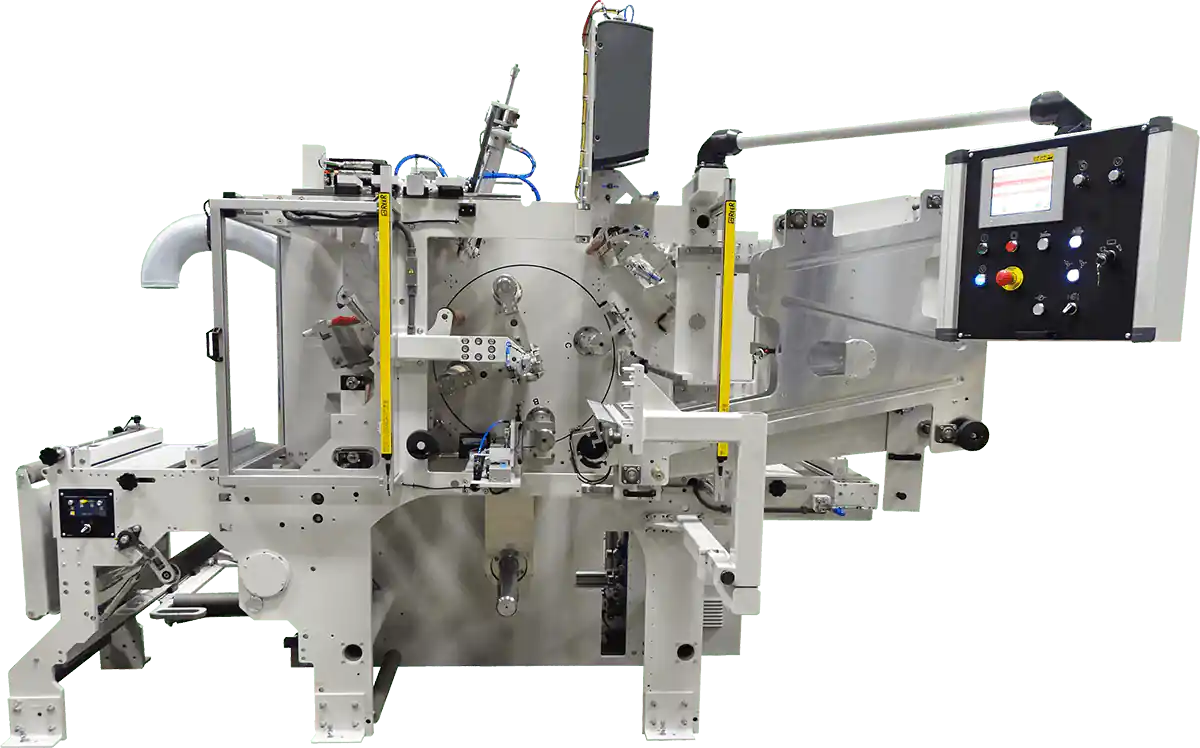

Opal Turret Slitter Rewinder

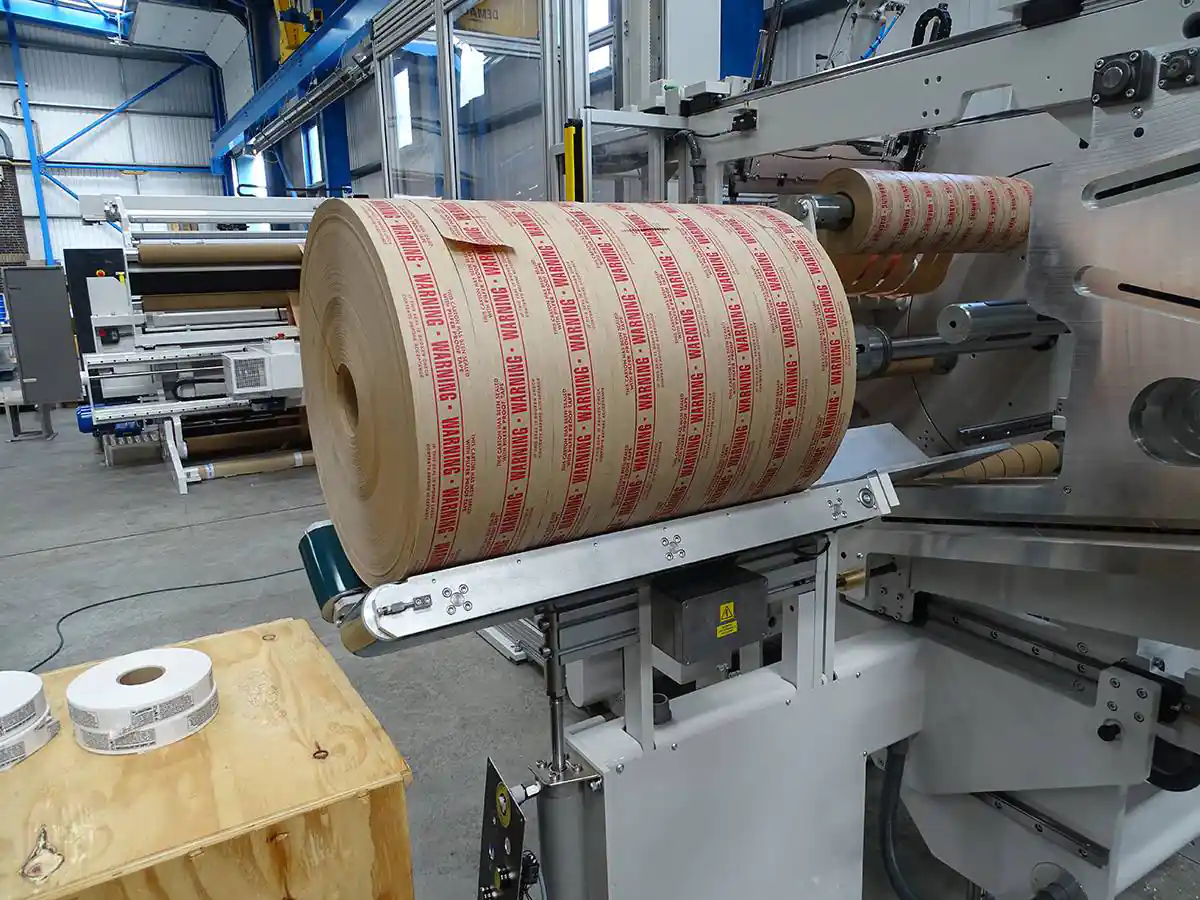

ASHE’s Opal Turret Slitter rewinder can be set to run at a given length or number of labels, and it will then cut and transfer the web without stopping. Each turret slitter rewinder can run light or high tension to allow a wider range of materials to run on one machine.

Enquiry

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.

OpalNarrow-Web Label Inline and Offline Turret Rewinder

The Opal range of glueless turret slitter rewinders is in a class of its own. The benefit of these turret slitter rewinders is that the changeover from one set job to the next is automatic and can be completed within minutes. This saves hours in lost setup times as the turret slitter rewinders can continuously run, having only to stop when the master roll needs replacing or the printing process stops.

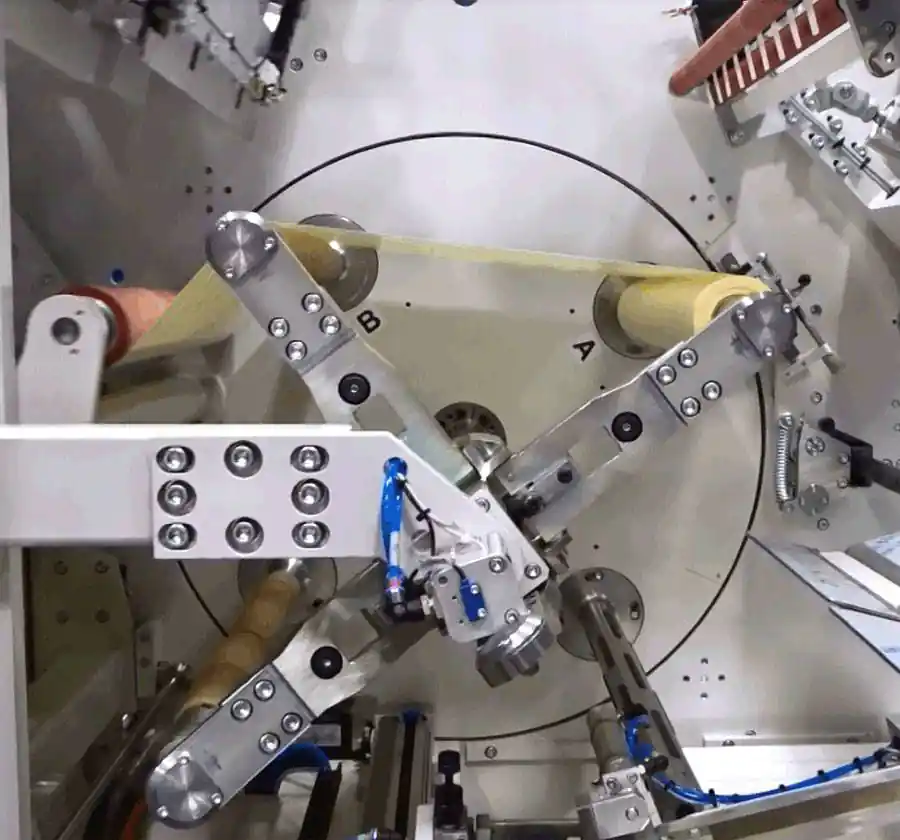

ASHE has a patented solution for starting on a new core at speed without the need to apply glue or tape to it. Our cinch mechanism allows this to happen at speed and gives a perfect, tuck-and-fold-free start onto the new incoming core. In addition to this operation, the finished rolls can also be closed with a label (plain or printed) to give a fast, clean and safe way of producing finished rolls in the fastest time possible.

- Features

- Specifications

- Gallery

- Video

- Brochure

- Fully automatic four-spindle glueless turret rewinder

- No changeover times involved (other than rewind shaft changeover)

- Can run inline with existing processes, such as printing presses or die cutting units, or be a totally separate offline operation

- Full servo operation with one servo motor on each rewind shaft

- Clean and safe operation with no heated glue in the machine

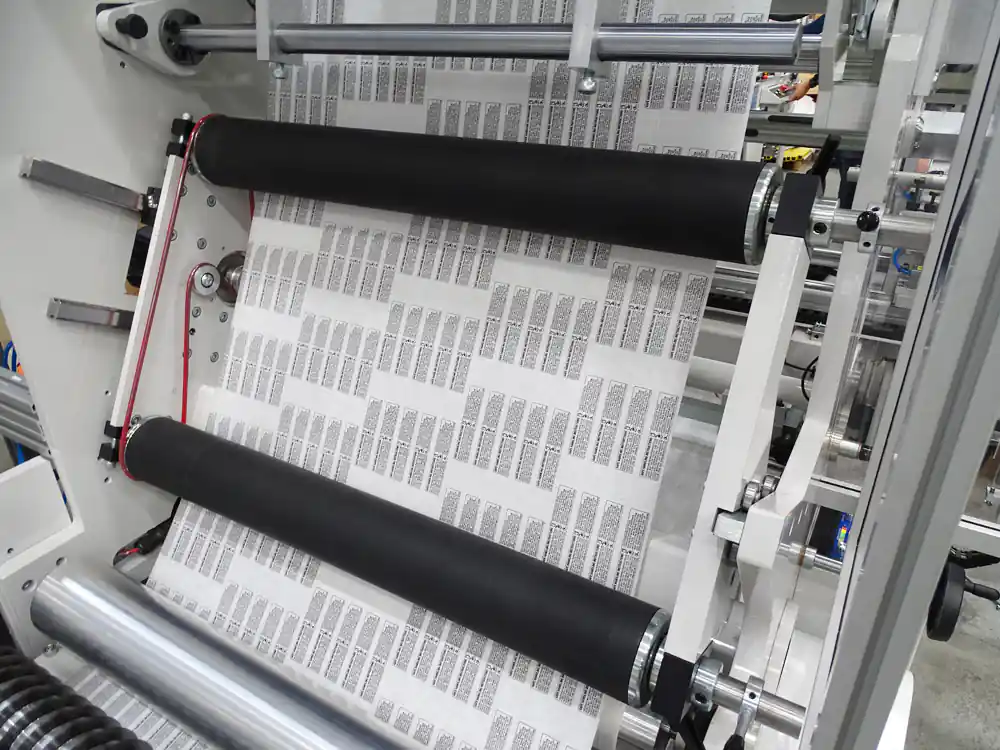

- Integration of 100% camera inspection systems

- Cost-saving benefits with no glue costs and energy saving, as no glue to heat

- A full shaft support mechanism is available on small cores so that shafts remain fully supported throughout the turret cycle and run operation

- Available with various automatic core loading facilities to reduce operator involvement and save further time

- Automatic roll eject system

- Slitting station available with rotary shear, razor, or crush slitting

- Full ASHE edge guiding available

- Patented glueless system to apply onto incoming core at speeds of 150m/min

- Label applicator for closing of finished rolls, which can also be linked to thermal printers

- Easy lock/unlock, adjustable rewind shafts to run sizes of rewind core between 19mm and 102mm

- Length (metres or feet) and label count control

- Interlabel cutting is possible

- Unwind options with integral unwind or separated unwind for larger roll diameters

| Material width | 340mm (13″) 440mm (17″) 540mm (21″) 600mm(24″) |

| Maximum rewinding diameter | 400mm (16″) 600mm (24″) |

| Machine speed | 230m/min (755ft/min) |

| Cut and transfer speed | 150m/min (492ft/min) on core sizes 40mm and above |

| Materials to be run | Paper and film PS materials |

| Operation | Direct AC Servo with HMI touch screen |

Download this brochure as a PDF:

Finishing equipment for the label and narrow web industriesInline/Offline Narrow-Web Turret RewinderKey Features

Enquire about the Opal turret rewinder

Discover why our clients choose us for their slitter rewinders and converting machinery.

Enquiry

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.