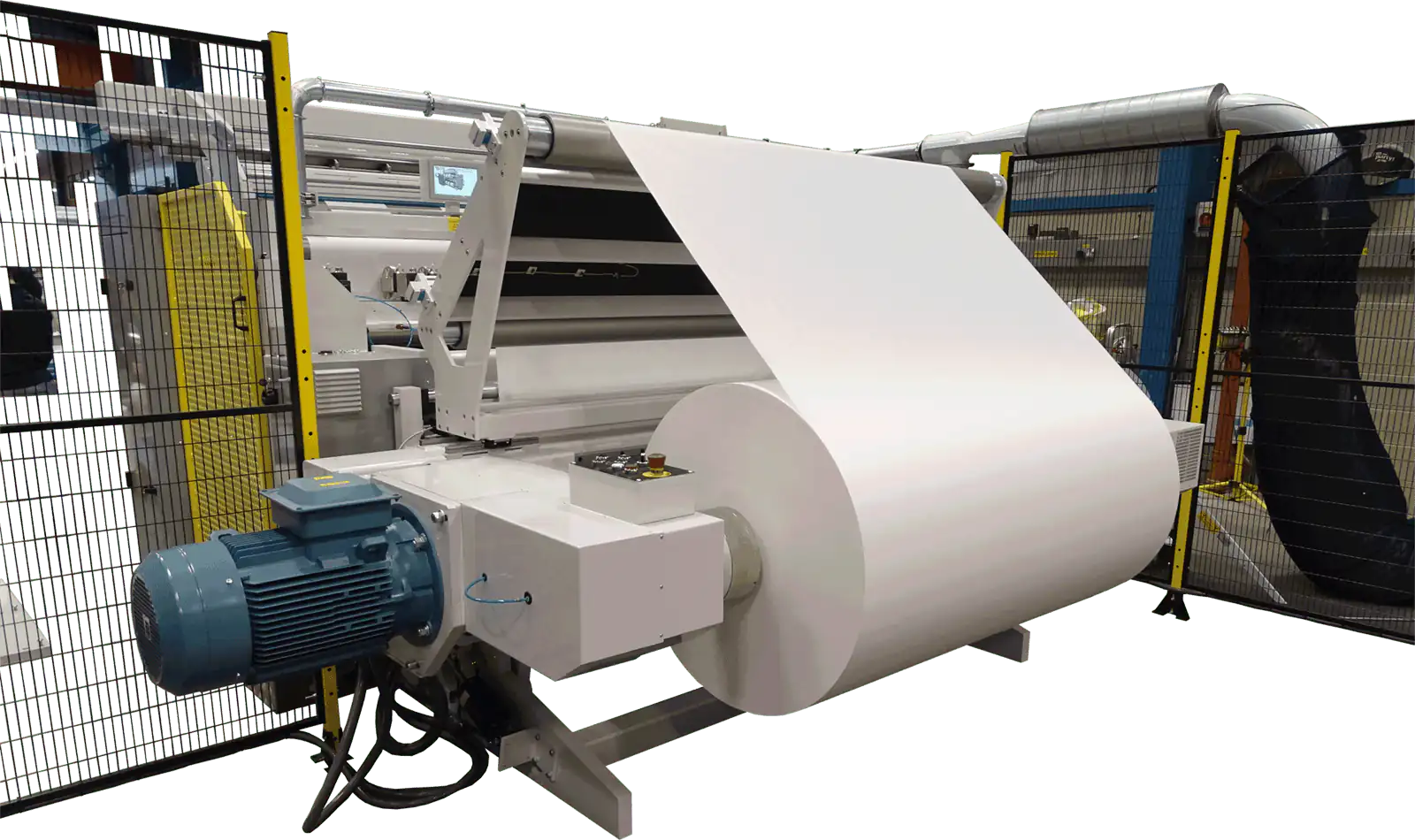

Sapphire S2

The only choice for ease of operation, repeatability and minimal downtime. The Sapphire S2 slitter rewinder is acclaimed for its versatility in being able to handle many different products, without any changes to the machine operation.

Enquiry

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.

Sapphire S2Wide-Web Duplex Slitter Rewinder

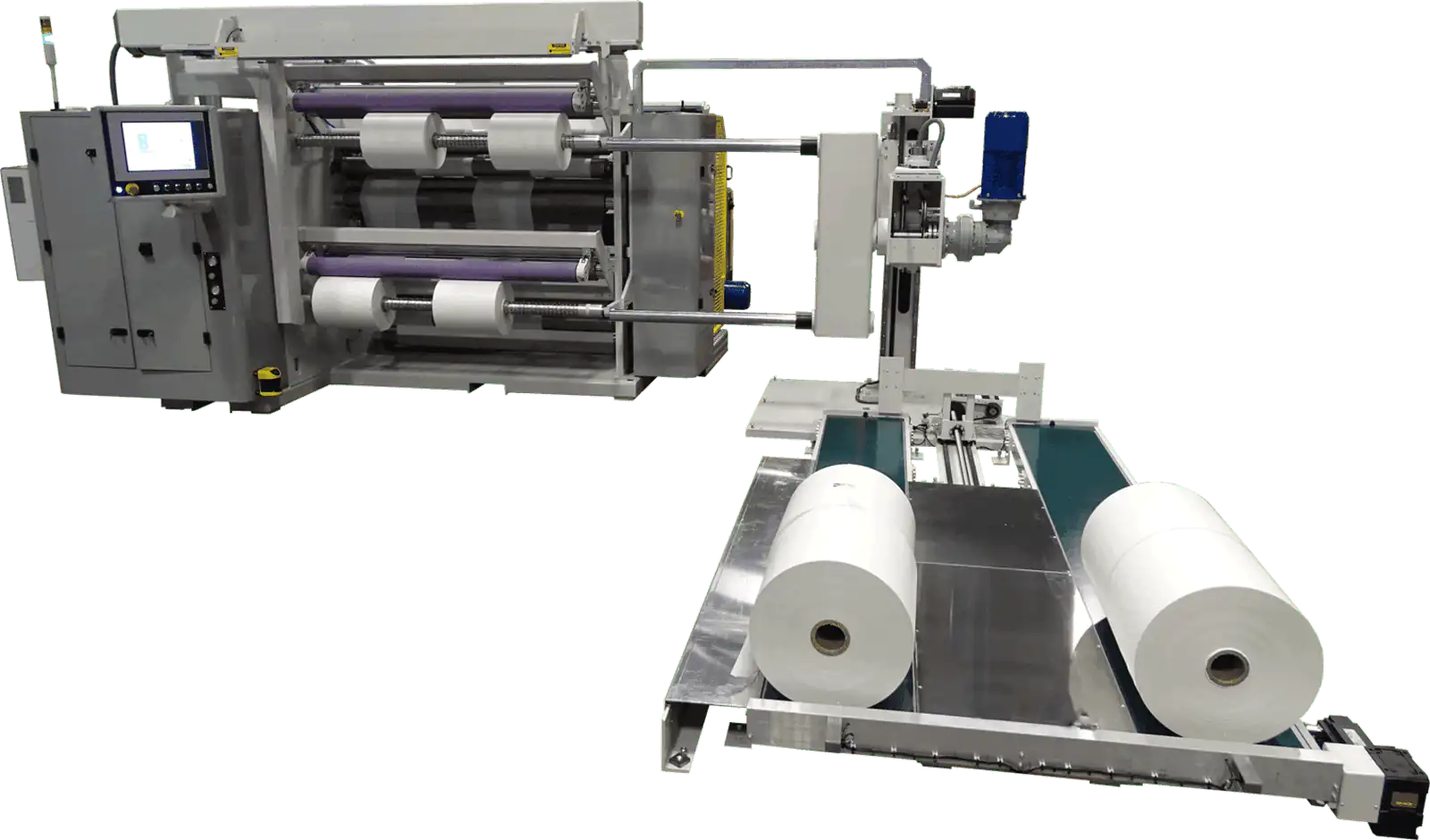

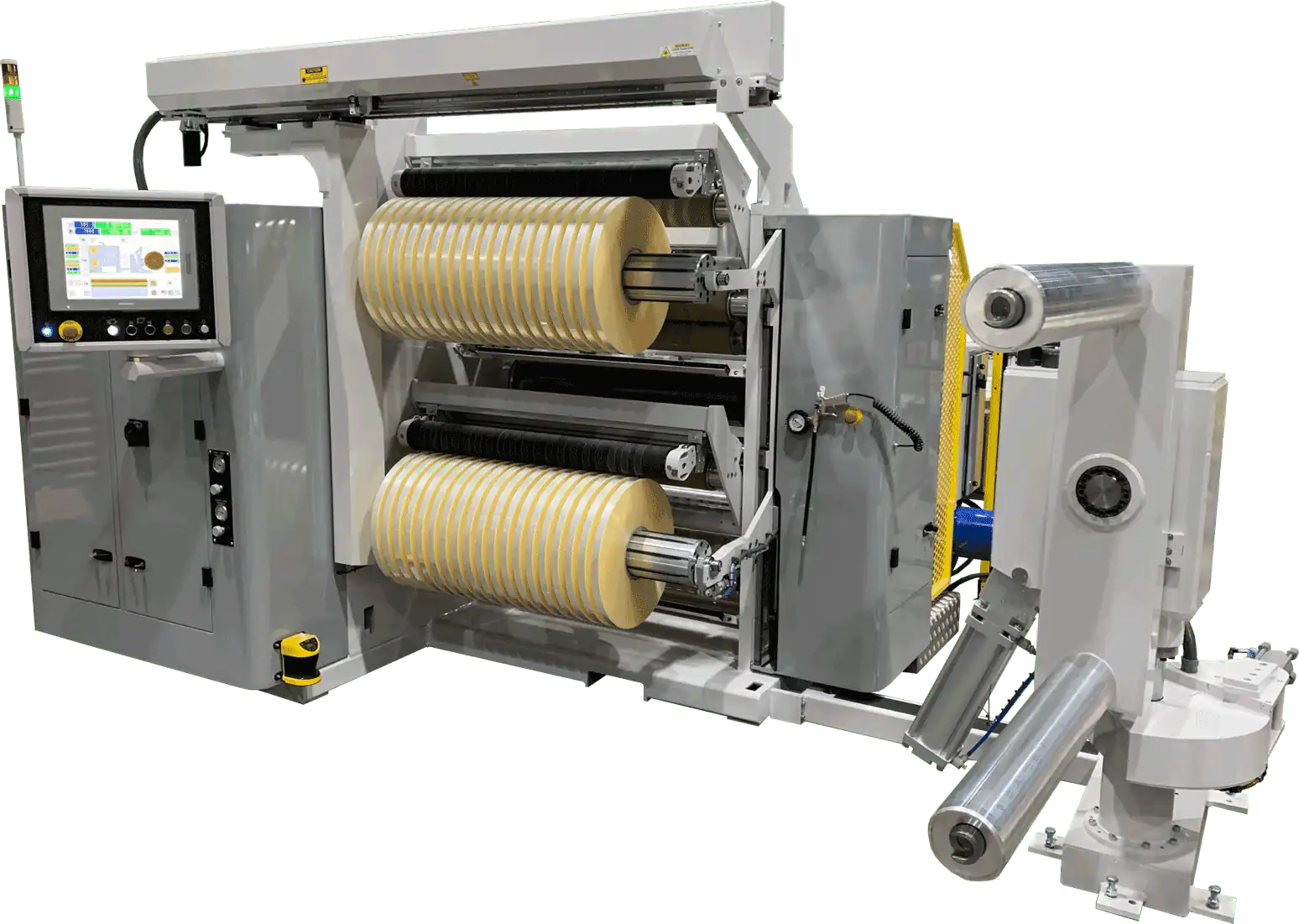

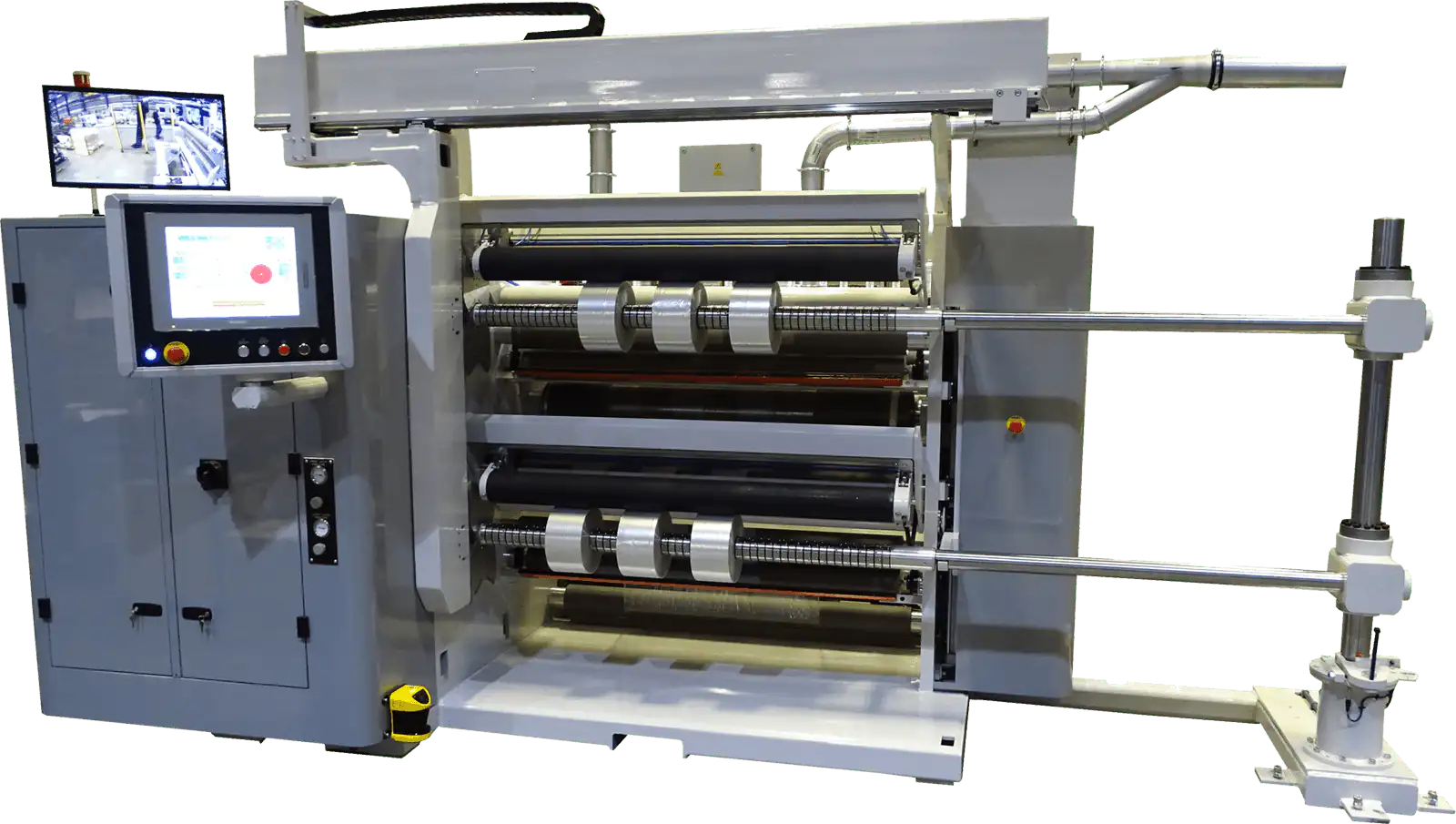

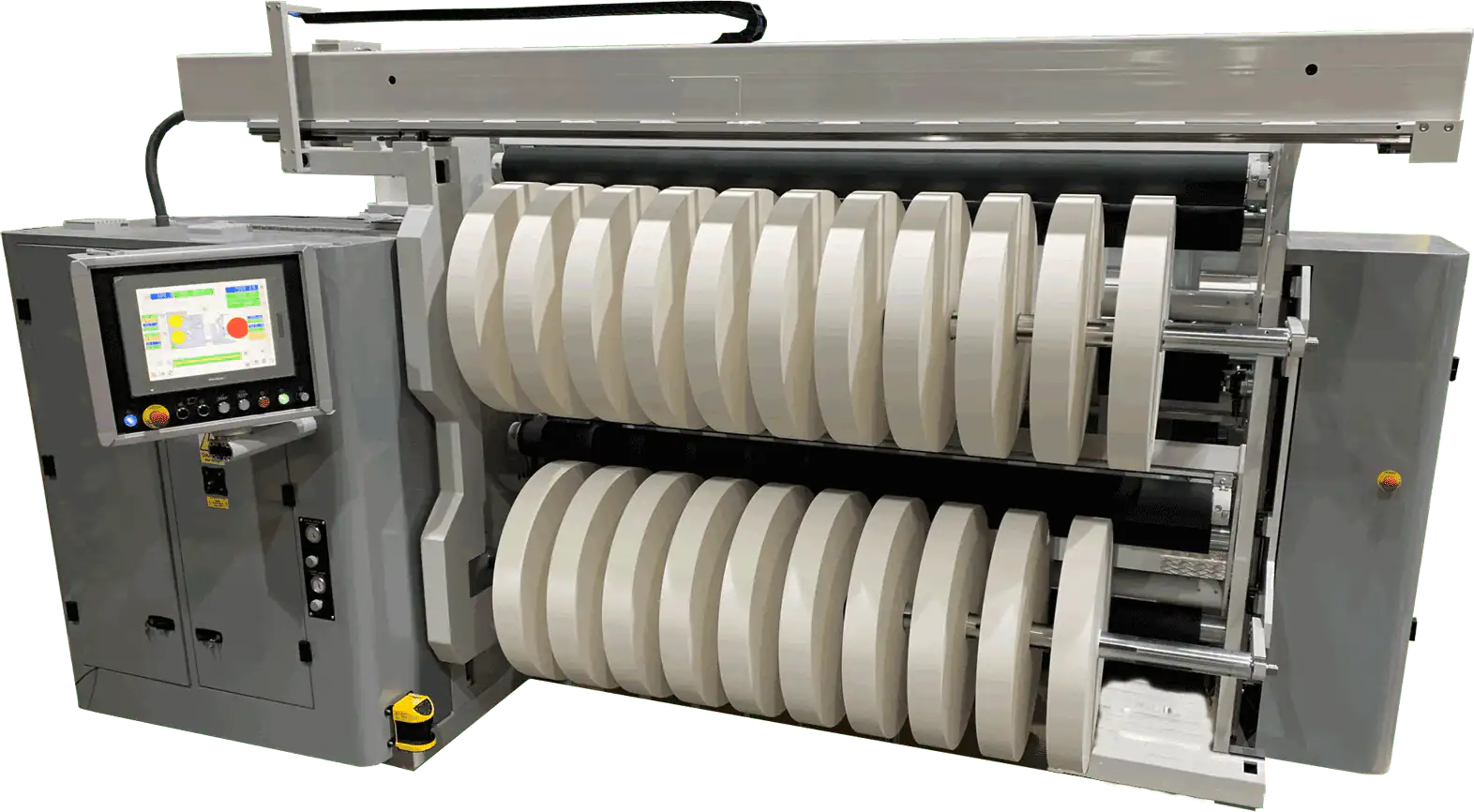

Our flagship duplex slitter rewinder is designed to process all flexible material substrates, at high speeds with ultimate precision. The concept of this slitter rewinder is to offer a simple manual solution through to a fully automated slitter rewinder that has minimal operator intervention.

Using the latest control technology makes the machine extremely easy to operate and gives the machine the flexibility many converters demand. The machine is available in various unwind configurations to suit most applications and products.

All forms of slitting can be accommodated on the Sapphire s2 and there is a range of automation solutions on the slitting station for ease and speed of knife setup. This automation can also continue to the rewind section where features such as automatic core indication, or automatic core positioning can be accommodated.

This slitting machine is the cleanest solution for flexible packaging and for medical products as there are no hydraulics on the machine. All unwind movements are powered electrically. Our vacuum roller technology is also on the machine to give perfect tension isolation between the unwind and rewind which requires no operator intervention or maintenance.

Roll handling solutions from the rewind can also be offered within the machine package which can range from simple fixed pedestals, to full robotics with wrapping and labelling.

- Features

- Specifications

- Gallery

- Video

- Brochure

- Shaftless unwind with independently movable arms

- Electric roll lifting system which uses no hydraulics

- Braked unwind or driven with dancer roller for optimal tension control

- Integrated splicing table for seamless roll joining

- Full web guiding with ASHE own edge / line guider for all materials

- Tension isolation via vacuum roller

- Compatibility with all slitting formats

- Full automation can be offered with automatic knife / blade positioning available for all forms of slitting

- Laser aided positioning or digital readout systems available for slitting

- ASHE differential (friction) winding shafts which require NO LUBRICATION

- Flexible rewind tension control with open or closed-loop systems

- Individual motors and drives for each rewind shaft

- Driven layon (Contact) roller system with different widths available

- Intuitive HMI with memory functions for efficient operation

- Remote diagnostics and data transfer capabilities

| Material width | 1000mm (40″) to 2000mm (80″) |

| Parent roll diameter | Up to 1800mm (40″) |

| Maximum rewinding diameter | 600mm (24″) 800mm (32″) 1000mm (40″) depending upon application |

| Slitting methods | All slitting methods available |

| Slitting widths | Minimum 25mm (1″) |

| Machine speed | 800m/min (2624ft/min) |

Download this brochure as a PDF:

ASHE Product RangeS2 Slitter RewinderKey Features

About Duplex Turret Slitter Rewinders

Discover why our clients choose us for their slitter rewinders and converting machinery.

Enquiry

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.